HIGH LIFT & HIGH CAPACITY, FULL NOZZLE CONSTRUCTION, DIRECT SPRING LOADED, METAL TO METAL SEAT, SIZE 1” TO 8” (‘D’ TO ‘T’ ORIFICE IN ACCORDANCE WITH API-526) FLANGED END ANSI 150# TO 2500# (TEMP.- 196ºC TO +530ºC SAFETY/PRESSURE RELIEF VALVE. SET PRESSURE RANGE 1 BAR TO 414 BAR

DESIGN FEATURE

- Face to face dimension according to API 526

- Adjusting and reaction rings

- Screwed full nozzle

- Flanges according to ANSI B 16.5

- Sizing & selection of safety relief valve in accordance with API 520, Part-I (Using API-520 coefcient & API-526 effective discharge area)

CONSTRUCTION

Body Materials

- Carbon steel code 3336

- Stainless steel code 3356

- Cr Mo steel code 3366

- Low temperature steel code 3376 Special materials included compliance to standard NACE MRO175

ACCESSORIES / OPTIONS

- Face to face dimension according to API 526

- Adjusting and reaction rings

- Screwed full nozzle

- Flanges according to ANSI B 16.5

- Sizing & selection of safety relief valve in accordance with API 520, Part-I (Using API-520 coefcient & API-526 effective discharge area)

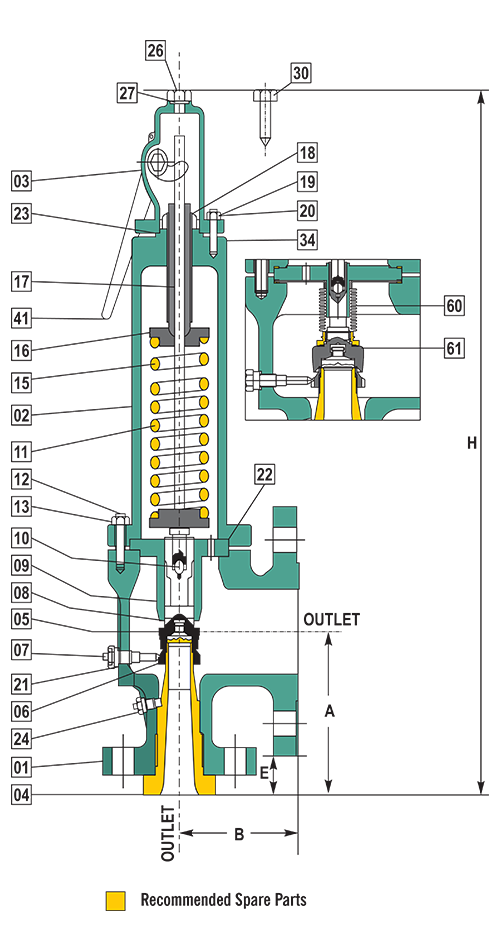

| PRESSURE RELIEF VALVES FLANGED TYPE SERIES : AK – 33 | |||||

|---|---|---|---|---|---|

| PART LIST | |||||

| PART LIST | AK-3336 CARBON STEEL | AK-3356 STAINLESS STEEL CORROSIVE SERVICE | AK-3366 CR MO STEEL | AK-3376 LOW TEMPERATURE | |

| PART NO | DESCRIPTION | TEMP-29oC TO 427oC | TEMP-196oC TO 530oC | TEMP-29oC TO 538oC | TEMP-30oC TO 345oC |

| 01 | Body | A 216 GR WCB | A 351 GR CF8M | A 217 GR WC6 | A 352 GR LCB |

| 02 | Bonnet | A 216 GR WCB | A 351 GR CF8M | A 217 GR WC6 | A 352 GR LCB |

| 03 | Cap | A 216 GR WCB | A 351 GR CF8M | A 217 GR WC6 | A 352 GR LCB |

| 04(R) | Nozzle | SS-316 / CF8M | SS-316 / CF8M | SS-316 / CF8M | SS-316 / CF8M |

| 05(R) | Disc | SS-316 | SS-316 | SS-316 | SS-316 |

| 06 | Adj. Ring | A 351 GR CF8M | A 351 GR CF8M | A 351 GR CF8M | A 351 GR CF8M |

| 07 | Adj. Ring Pin | SS-304 | SS-304 | SS-304 | SS-304 |

| 08 | Disc Holder / Piston | SS -304/351 GR CF8 | SS -304/351 GR CF8 | SS -304/351 GR CF8 | SS -304/351 GR CF8 |

| 09 | Guide | SS-316/A 351 GR CF8M | SS-316/A 351 GR CF8M | SS-316/A 351 GR CF8M | SS-316/A 351 GR CF8M |

| 10 | Ball | SS – 304 | SS – 304 | SS – 304 | SS – 304 |

| 11 | Spindle | SS – 304 | SS – 304 | SS – 304 | SS – 304 |

| 12 | Body – Bonnet Bolting Stud | A 193 GR B7 | A 193 GR B8 | A 193 GR B7 | A 193 GR B7 |

| 13 | Body – Bonnet Bolting Nut | A 194 GR 2H | A 194 GR 8H | A 194 GR 2H | A 197 GR 2H |

| 15 (R) | Spring | ACCORDING TO MEDIUM AND TEMPERATURE | |||

| 16 | Spring Washer | C. S. | SS-304 | SS-304 | C. S. |

| 17 | Adj. Screw | SS-304 | SS-304 | SS-304 | SS-304 |

| 18 | Lock Nut | SS-304 | SS-304 | SS-304 | SS-304 |

| 19/20 | Cap – Bonnet Fastener | CARBON STEEL | SS-304 | CARBON STEEL | CARBON STEEL |

| 21 | Set Screw Gasket | GRAPHOIL WITH SS FILLER | GRAPHOIL WITH SS FILLER | GRAPHOIL WITH SS FILLER | GRAPHOIL WITH SS FILLER |

| 22 | Guide Gasket | GRAPHOIL WITH SS FILLER | GRAPHOIL WITH SS FILLER | GRAPHOIL WITH SS FILLER | GRAPHOIL WITH SS FILLER |

| 23 (R) | Cap Gasket | GRAPHOIL WITH SS FILLER | GRAPHOIL WITH SS FILLER | GRAPHOIL WITH SS FILLER | GRAPHOIL WITH SS FILLER |

| 24 | Drain Plug | SS-304 | SS-304 | SS-304 | SS-304 |

| 26 | Cap Plug | C.S. | SS-304 | C.S. | C.S. |

| 27 (R) | Plug Gasket | GRAPHOIL WITH SS FILLER | GRAPHOIL WITH SS FILLER | GRAPHOIL WITH SS FILLER | GRAPHOIL WITH SS FILLER |

| 30 | Test Gag | C.S. | SS-304 | C.S. | C.S. |

| 41 | Lever Assembly | A 479 410 | A 479 304 | A 479 410 | A 479 410 |

| 60 (R) | Bellow | SS-316 L | SS-316 L | SS-316 L | SS-316 L |

| 61 (R) | Bellow Gasket | GRAPHOIL WITH SS FILLER | GRAPHOIL WITH SS FILLER | GRAPHOIL WITH SS FILLER | GRAPHOIL WITH SS FILLER |

| (R) : Recommended Spares Other materials on Request | Recommended Spring Materials | |

|

COLD DIFFERENTIAL TEST PRESSURE (CDTP:)

|

Material | Temp Range (OC) |

| 1. Carbon Steel (C.S. with Plating) 2. High Temp Alloy Steel (HTAS) a. 50 CrV4 (Chrome Alloy) b. Tungsten Alloy c. Inconel 3. Low Temp Alloy Steel (SS) |

-59 to 232 -59 to 350 -59 to 538 -196 to 538 -196 to 260 |

|

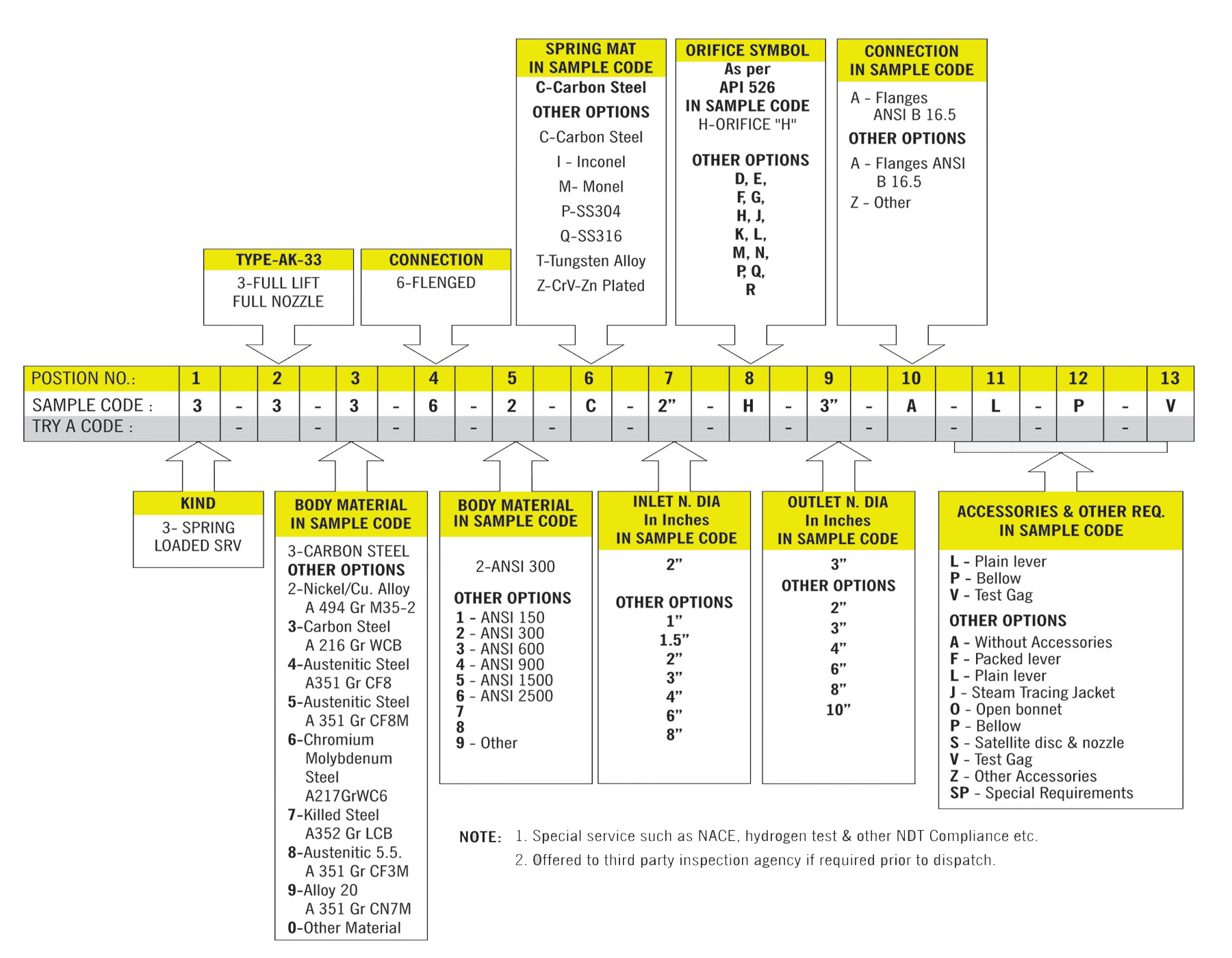

| PRESSURE RELIEF VALVES FLANGED TYPE SERIES : AK – 33 |

|---|

| CODIFICATION NUMBERING SYSTEM |

| 114PRESSURE RELIEF VALVES FLANGED TYPE SERIES : AK – 33 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| SIZES | ||||||||||

| ORIFICE | FLANGES ANSI RF * | MAX SET PRESSURE AT 38o C (BAR-g) |

DIMENSIONS | APPROX WEIGHT (KG) |

||||||

| API – 526 | ND in. Inlet x Outlet |

CLASS ANSI | ±3 A mm |

±3 B mm |

±3 E mm |

±10 H mm |

||||

| DESIGNATION | EFFECTIVE AREA (cm2 ) Sq In |

INLET | OUTLET | |||||||

| D | (0.71) 0.11 |

1″ x 2″ | 150 | 150 | 19.6 | 105 | 114 | 32.5 | 420 | 18 |

| 300 | 150 | 19.6 | 105 | 114 | 32.5 | 420 | 18 | |||

| 300 | 150 | 51 | 105 | 114 | 32.5 | 420 | 18 | |||

| 600 | 150 | 102 | 105 | 114 | 32.5 | 420 | 18 | |||

| 1.5″ x 2″ | 900 | 300 | 153 | 105 | 140 | 40.5 | 512 | 30 | ||

| 1500 | 300 | 255 | 105 | 140 | 40.5 | 512 | 30 | |||

| 1.5″ x 3″ | 2500 | 300 | 414 | 140 | 178 | 60 | 640 | 42 | ||

| E | (1.26) 0.196 |

1″ x 2″ | 150 | 150 | 19.6 | 105 | 114 | 32.5 | 420 | 18 |

| 300 | 150 | 19.6 | 105 | 114 | 32.5 | 420 | 18 | |||

| 300 | 150 | 51 | 105 | 114 | 32.5 | 420 | 18 | |||

| 600 | 150 | 102 | 105 | 114 | 32.5 | 420 | 18 | |||

| 1.5″ x 2″ | 900 | 300 | 153 | 105 | 140 | 40.5 | 512 | 30 | ||

| 1500 | 300 | 255 | 105 | 140 | 40.5 | 512 | 30 | |||

| 1.5″ x 3″ | 2500 | 300 | 414 | 140 | 178 | 60 | 640 | 42 | ||

| F | (1.98) 0.307 |

1″ x 2″ | 150 | 150 | 19.6 | 124 | 121 | 34 | 530 | 30 |

| 300 | 150 | 19.6 | 124 | 121 | 34 | 530 | 30 | |||

| 300 | 150 | 51 | 124 | 152 | 38 | 530 | 36 | |||

| 600 | 150 | 102 | 124 | 152 | 38 | 530 | 36 | |||

| 1.5″ x 3″ | 900 | 300 | 153 | 124 | 165 | 47 | 554 | 48 | ||

| 1500 | 300 | 255 | 124 | 165 | 47 | 554 | 48 | |||

| 2500 | 300 | 345 | 140 | 178 | 60 | 640 | 60 | |||

| G | (3.24) 0.503 |

1.5″ x 3″ | 150 | 150 | 19.6 | 124 | 121 | 34 | 540 | 30 |

| 300 | 150 | 19.6 | 124 | 121 | 34 | 540 | 30 | |||

| 300 | 150 | 51 | 124 | 152 | 38 | 540 | 36 | |||

| 600 | 150 | 102 | 124 | 152 | 38 | 540 | 36 | |||

| 900 | 300 | 153 | 124 | 165 | 47 | 650 | 42 | |||

| 2″ x 3″ | 1500 | 300 | 255 | 156 | 171 | 64 | 740 | 78 | ||

| 2500 | 300 | 255 | 156 | 171 | 64 | 740 | 84 | |||

| H | (5.06) 0.785 |

1.5″ x 3″ | 150 | 150 | 19.6 | 130 | 124 | 36 | 540 | 35 |

| 300 | 150 | 19.6 | 130 | 124 | 36 | 540 | 35 | |||

| 2″ x 3″ | 300 | 150 | 51 | 130 | 124 | 36 | 540 | 35 | ||

| 600 | 150 | 102 | 155 | 162 | 42 | 700 | 48 | |||

| 900 | 150 | 153 | 155 | 162 | 63 | 730 | 78 | |||

| 1500 | 300 | 190 | 155 | 162 | 63 | 730 | 82 | |||

| J | (8.3) 1.287 |

2″ x 3″ | 150 | 150 | 19.6 | 137 | 124 | 36 | 559 | 35 |

| 300 | 150 | 19.6 | 137 | 124 | 36 | 559 | 35 | |||

| 3″ x 4″ | 300 | 150 | 51 | 184 | 143 | 47 | 725 | 58 | ||

| 600 | 150 | 102 | 184 | 181 | 49 | 750 | 98 | |||

| 900 | 150 | 153 | 184 | 181 | 53 | 970 | 132 | |||

| 1500 | 300 | 186 | 184 | 181 | 67 | 771 | 145 | |||

| K | (11.86) 1.838 |

3″ x 4″ | 150 | 150 | 19.6 | 156 | 162 | 43.5 | 700 | 78 |

| 300 | 150 | 19.6 | 156 | 162 | 43.5 | 700 | 78 | |||

| 300 | 150 | 51 | 156 | 162 | 43.5 | 700 | 78 | |||

| 600 | 150 | 102 | 184 | 181 | 53 | 970 | 130 | |||

| 3″ x 6″ | 900 | 150 | 153 | 198 | 216 | 54 | 1160 | 156 | ||

| 1500 | 300 | 153 | 198 | 216 | 67 | 1160 | 210 | |||

| L | (18.41) 2.853 |

3″ x 4″ | 150 | 150 | 19.6 | 156 | 165 | 43.5 | 700 | 78 |

| 300 | 150 | 19.6 | 156 | 165 | 43.5 | 700 | 78 | |||

| 4″ x 6″ | 300 | 150 | 51 | 179 | 181 | 44 | 990 | 130 | ||

| 600 | 150 | 69 | 179 | 203 | 52.5 | 1000 | 180 | |||

| 900 | 150 | 103 | 197 | 222 | 61 | 1160 | 210 | |||

| 1500 | 150 | 103 | 197 | 222 | 71 | 1160 | 222 | |||

| M | (23.2) 3.6 |

4″ x 6″ | 150 | 150 | 19.6 | 178 | 184 | 44 | 990 | 108 |

| 300 | 150 | 19.6 | 178 | 184 | 44 | 990 | 130 | |||

| 300 | 150 | 51 | 178 | 184 | 44 | 990 | 130 | |||

| 600 | 150 | 76 | 178 | 203 | 52.5 | 1000 | 180 | |||

| 900 | 150 | 76 | 197 | 222 | 61 | 1160 | 210 | |||

| N | (28) 4.34 |

4″ x 6″ | 150 | 150 | 19.6 | 197 | 210 | 46 | 1010 | 90 |

| 300 | 150 | 19.6 | 197 | 210 | 46 | 1010 | 130 | |||

| 300 | 150 | 51 | 197 | 210 | 46 | 1010 | 130 | |||

| 600 | 150 | 69 | 197 | 222 | 61 | 1010 | 205 | |||

| 900 | 150 | 69 | 197 | 222 | 61 | 1010 | 210 | |||

| P | (41.2) 6.38 |

4″ x 6″ | 150 | 150 | 19.6 | 181 | 229 | 46 | 1000 | 136 |

| 300 | 150 | 19.6 | 181 | 229 | 46 | 1000 | 132 | |||

| 300 | 150 | 36 | 225 | 254 | 46.5 | 1060 | 180 | |||

| 600 | 150 | 69 | 225 | 254 | 60 | 1200 | 264 | |||

| 900 | 150 | 69 | 225 | 254 | 60 | 1200 | 270 | |||

| Q | (103) 16 |

6″ x 8″ | 150 | 150 | 11.5 | 240 | 241 | 43.5 | 1100 | 192 |

| 300 | 150 | 11.5 | 240 | 241 | 54 | 1120 | 264 | |||

| 300 | 150 | 21 | 240 | 241 | 54 | 1120 | 264 | |||

| 600 | 150 | 42 | 240 | 241 | 67.5 | 1133 | 288 | |||

| R | (103) 16 |

6″ x 8″ | 150 | 150 | 7 | 240 | 241 | 43.5 | 1100 | 198 |

| 300 | 150 | 7 | 240 | 241 | 54 | 1120 | 270 | |||

| 6″ x 10″ | 300 | 150 | 16 | 240 | 241 | 54 | 1205 | 282 | ||

| 600 | 150 | 21 | 240 | 241 | 63 | 1205 | 306 | |||

| T | (168) 26.00 |

8″ x 10″ | 150 | 150 | 4.5 | 276 | 279 | 47 | 1346 | 408 |

| 300 | 150 | 8 | 276 | 279 | 60 | 1400 | 436 | |||

| 300 | 150 | 21 | 276 | 279 | 60 | 1400 | 426 | |||